Fabrication Stamping Sheet Metal Speaker Enclosure CNC Milling Stamping Parts

Overview Package Size 45.00cm * 40.00cm * 30.00cm Package Gross Weight 20.000kg Fabrication Stamping Sheet Metal Speaker

Description

Basic Info.

| Model NO. | PPL-S010005 |

| Processing Type | Shaping Metal |

| Material | Steel, Aluminum, Brass and Other Types |

| Mould | Simple Single Process Dies |

| Surface Processing | Powdercoated, Polishing, Electroplating, Anodizing |

| Fine Blanking | Customized |

| Process | Forming Process |

| Industry | Auto Industry, Furniture Industry, Solar Energy etc. |

| Tolerances | International Standard |

| Customized | Customized |

| Leadtime | 4-6 Weeks |

| Packing | Carton Packaging, or PVC Bag with a Label; Wooden |

| Sample Delivery | 5-7 Days |

| Shipping Way | by Sea;by Air;Door to Door |

| Samples | Available |

| Working Process | Laser Cutting Bending Stamping Welding |

| Quality | 100% Inspection Before Shipping |

| Surface Treatment | Powdercoated, Polishing, Electroplating, Anodizin |

| Drawing | Provide by Customer(Dxf/Dwg/Prt/Sat/Iges/Step etc) |

| Customization | Available |

| Transport Package | Carton |

| Specification | Customize |

| Trademark | Customize |

| Origin | Xiamen, China |

| HS Code | 7326909000 |

| Production Capacity | 2000-10000PCS/Day |

Packaging & Delivery

Package Size 45.00cm * 40.00cm * 30.00cm Package Gross Weight 20.000kgProduct Description

Fabrication Stamping Sheet Metal Speaker Enclosure CNC Milling Stamping Parts

1. Free design and free sample.

2. Sign NDA.

3. ISO Certificated with the strict quality control system.

4. 13 Years OEM&ODM Metal Stamping experience.

5. Good at spoken english and phone call communication.

6. One stop solution and drop shipment for online sellers.

Product Description

| Custom Precision Metal Stamping Parts | |

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Material | Steel, Stainless Steel, Brass, Copper, bronze, Aluminum, Titanium, silicon steel, nickel plate, etc. |

| Processing | Precision Stamping, Bending, CNC Punching, Laser Cutting, Threading, Riveting, Drilling, Welding etc |

| SurfaceTreatment | Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, Sandblast, etc |

| Thicknees | 0.1mm-10mm |

| Tolerance | +/-0.1mm, 100% QC quality inspection before delivery, can provide quality inspection form |

| Logo | Silk print, Laser marking. |

| Size | Customized. |

| Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI,PDF, JPG, Draft. |

| Capacity | 2000K Pcs per day |

| Lead time | 2-3 Weeks |

| Certificate | ISO9001:2015 |

| Packing | By carton or as your request |

Services

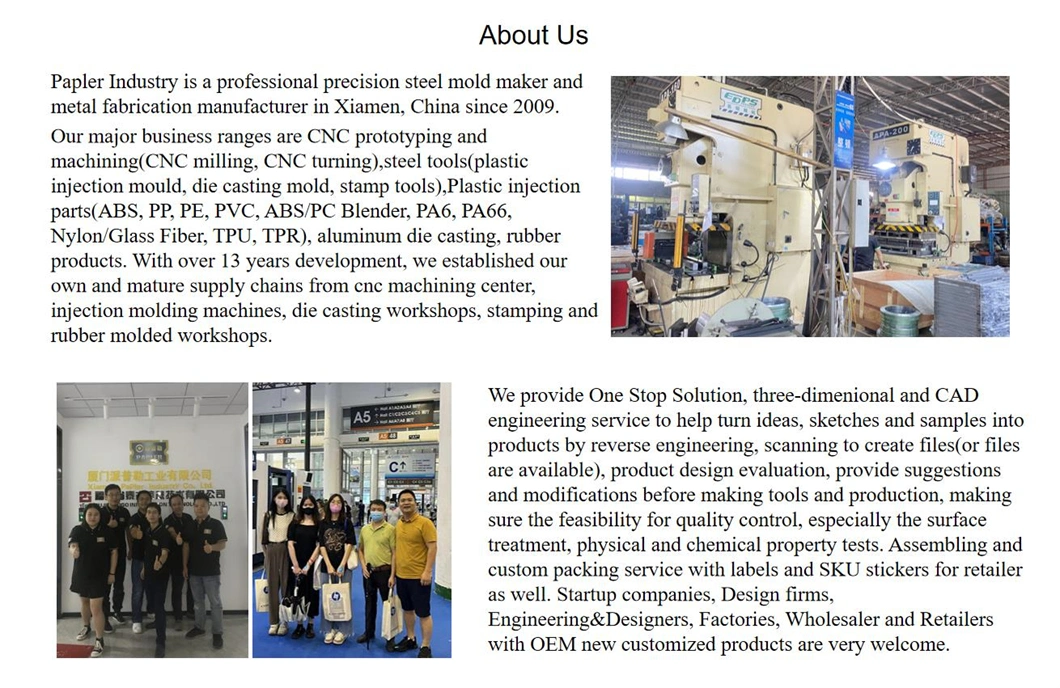

Papler Industry provides custom service of CNC machining, mould manufacturing, die casting, metal stamping, plastic injection molding and rubber molding. Our experience range from simple design to challenging technical parts.

Company Profile

Packaging & ShippingFAQ1. Q: Are you trading company or manufacturer ? A: We are direct factory with experienced engineers and employees as well as well-organized workshop.2. Q: How long is your delivery time? A: Generally is 15-20 days, it is according to quantity.3. Q: Do you provide samples ? is it free or extra ? A: Yes, the sample fee depends on the product geometry, and the fee will be returned to your bulk order.4. Q: How long can I get the sample? A: Depends on your part geometry, normally within 3-7 days.5. Q: How long is your delivery time? A: Sample 3-7days; Mass production order 7-45 days depends on quantity and part complexity.6. Q: What's kinds of information you need for a quote? A: Kindly please provide the product 2D drawing with PDF or DWG format and 3D drawings with STEP or IGS or X_T format, and other requirements like:material, surface treatment, quantity...etc.7. Q: What is your standard PO procurement process flow? A: Prototyping ----> FA approval ----> Quality Control Plan ---> Manufacturing Process Instruction ---> Batch Production ---> Inspection ---> Shipping8. Q: What shall we do if we do not have drawings? A. Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.9. Q: Will my drawings be safe after sending to you? A: Yes, we can sign the NDA before got your drawing and will not release to the third party without your permission.10. Q: Is it possible to know how are my products going on without visiting your company? A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos whichshow the machining progress11. Q: How to enjoy the OEM services? A: Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.If you have another question, pls feel free to contact us

Prev: Machining Precision Stainless Steel Ss Brass CNC Lathe Auto Hardware Aluminium Parts

Next: Rare Metal Pipeline Self

Our Contact

Send now